How To Pick The Perfect Heavy Duty Extension Cord For Your Needs

Extension cords are an indispensable fixture in modern workplaces, delivering much-needed electricity exactly where the workspace requires it.

People use them to power everything from vital lighting to high-load equipment over long distances. It is the extension cord cable that enables working some distance from the power outlet. These simple devices bridge the gap, making productivity possible in multiple locations. They are an essential part of every tool set or building installation.

Not all extension cords, however, meet the same rigorous standards for rugged use. Inserting a light-duty household cord into a heavy-duty shop tool invites serious calamity, in the way of tripped breakers, or, worse, insulation failure.

You want to protect investment in expensive equipment, and that requires a cord better suited for higher current draws and rougher treatment.

This article guides you through the right way to select the perfect heavy-duty cord for total peace of mind.

1. Check Power Requirements

Understanding the power requirements of your equipment is crucial before choosing an extension cord.

Check the amperage and wattage listed on the machine’s nameplate to know how much electricity it draws. The cord you select must sustain at least that load safely without overheating or causing voltage drops.

Ensure you choose a heavy duty extension cord with the proper power capacity for consistent performance. It helps prevent damage to both the tool and the extension cord.

Choosing a cord listed for less amperage than the tool requires causes overload. That causes the power cord to overheat, risking a fire hazard. Also, you may experience poor performance, and the motor in the tool may wear out prematurely from the power deficit.

Always verify that the amperage rating of the cord readily exceeds the requirements of the connected devices. The power cord should never be the weakest link in the supply chain.

2. Ensure Outdoor Rating

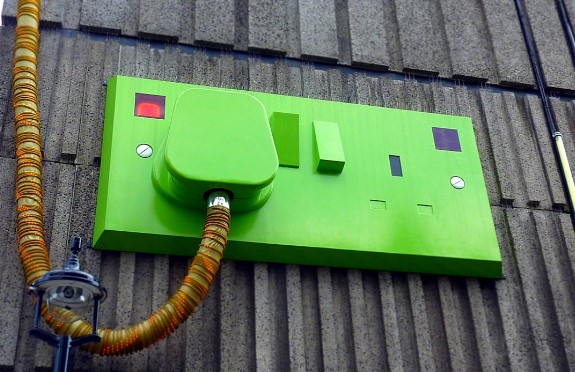

Heavy-duty applications are more common in construction sites, yards, or cold shops. Weatherproofing assumes an absolute necessity for any cord used outdoors, in a harsh, uncontrolled environment. The cord must have an outdoor rating, typically displayed by some letter or symbol on the jacket.

Outdoor-rated cords use heavy-duty insulation materials designed to repel water, resist degradation from sunlight, and withstand extreme temperatures.

The specially tough outer jacket also protects the interior wires from physical harm, such as nicks, cuts, and abrasion on rough surfaces. An interior cord jacket will quickly become brittle when subjected to sunlight and cold, and crack. Cracking exposes the conductors to immediate shock and fire risks to everything around them. They specifically make these hard-wearing cords to face harsh, unpredictable outdoor conditions.

3. Check Safety Labels

Carefully inspect the packing and the jacket on the cord itself for certificates from reputable, established testing laboratories.

Commonly accepted approvals are issued by institutions such as Underwriters Laboratories (UL) or Intertek (ETL). Their official marks guarantee that the cord has successfully undergone rigorous, impartial testing for national performance and safety standards.

Buying an uncertified cord for the sake of saving money is a risk nobody in the business takes.

4. Think about Cord Length

Select a cord with sufficient length to be accessible by the work area without having to yank it too hard or daisy-chain cords. Stretching any cord poses a dangerous tripping hazard, and daisy-chaining cords significantly increases the risk of overheating. The key is to select the shortest cord that still provides a free-moving range throughout the task. Longer cords do increase the risk of voltage drop, which impairs tool performance.

The optimal length is a balance between the working radius needed and the minimum power transmission demands. Remember, the longer cord requires a heavier gauge to compensate for greater electrical resistance and resulting power loss. For example, operating a high-amperage tool 100 feet away requires much heavier gauge wire than the short 25-foot pull. Achieving a conscientious balance between required reach and proper power transmission is essential.

5. Ensure Cable Flexibility

A notoriously stiff cord is very inconvenient to handle, especially during cold weather when the cover that normally hardens protects it. Spooling out and unspooling a flexible cable is easier, requiring less strength to wrap around obstructions on site. Look for cords constructed with jacket material like TPE or specialty vinyl compounds. Such materials excel in remaining flexible even at temperatures far below freezing levels.

Greater flexibility also prevents abrupt kinking, a prevalent problem that ruins the internal conductors and leads to premature cord failure. Nobody would ever want to invest time every time a job starts to untangle an entangled mess. A flexible cord makes it possible for it to operate like a professional tool, making work easy and reducing workday frustration. They offer better usability when being stored or installed.

The Bottomline

Buying the proper heavy-duty extension cord is more than simply picking a glowing hue or a set length.

The gauge must be compatible with the equipment’s power demand to prevent lethal overheating and voltage loss. Professionals check for the necessary safety ratings and outdoor ratings before committing.

These check steps ensure a safe and reliable system of power transfer that protects the tools and operator both for extended hours of rugged work.